Decolletatge Sabadell, S.L. is an enterprise dedicated to the metallurgical sector with more than fifty years of experience. We manufacture pieces of all types of material (metals and plastics).

WHO WE ARE

Thanks to our human equipment, production facilities and our latest generation machines, we offer a high quality, the meeting of the deadlines set by the agreements and the most competitive market prices.

- 1958

- 1969

- 1980

- 1999

- 2006

- 2007

- 2015

- 2016

- 2017

- 2020

PRODUCTS AND SERVICES

MATERIALS

METALS

Stainless steel · Iron·Steel (of construction and of alienation) · Aluminium·Bronzes · Copper · Brass · Titanium · Engineering

PLASTICS

Nylon · Nylatron · Delrin · Arnite · Bron-oil · Teflon · P.V.C · Polypropylene · Polyethylene (low P.M and high P.M) · Celotex · Methacrylate · Rexilon · Polycarbonate

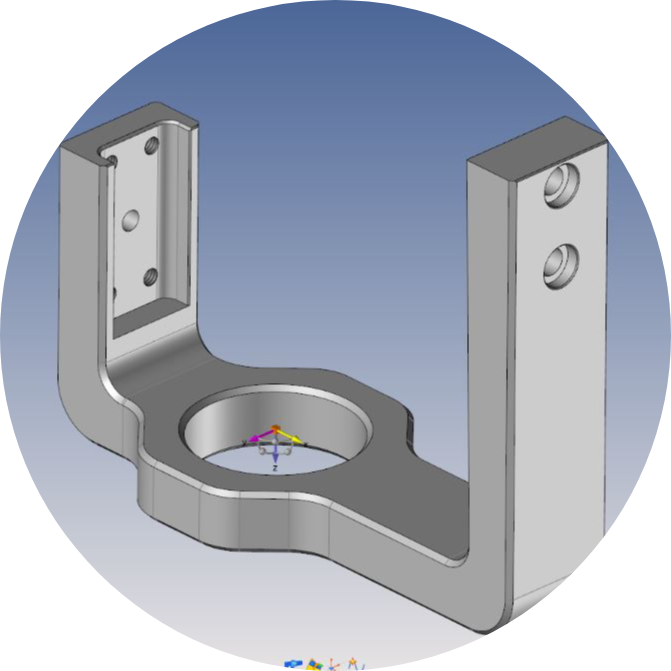

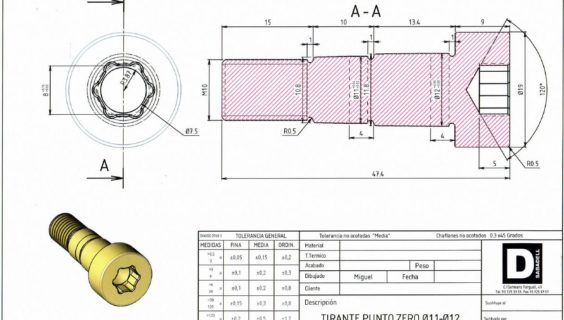

TECHNICAL OFFICE

The Technical Office allow us to ensure that we accomplish our values and goals of quality and maximum efficiency in every of the mechanizing processes, optimizing to the maximum the production times and the price of the pieces.

We design and develop pieces and products through the most sophisticated CAD-CAM programs of the market, and we invest every year in measuring instruments that allow us to obtain pieces without defects, preventing non-conformities.

All the above allow us to offer high quality products in reasonable deadlines; what it means security and tranquility for our clients.

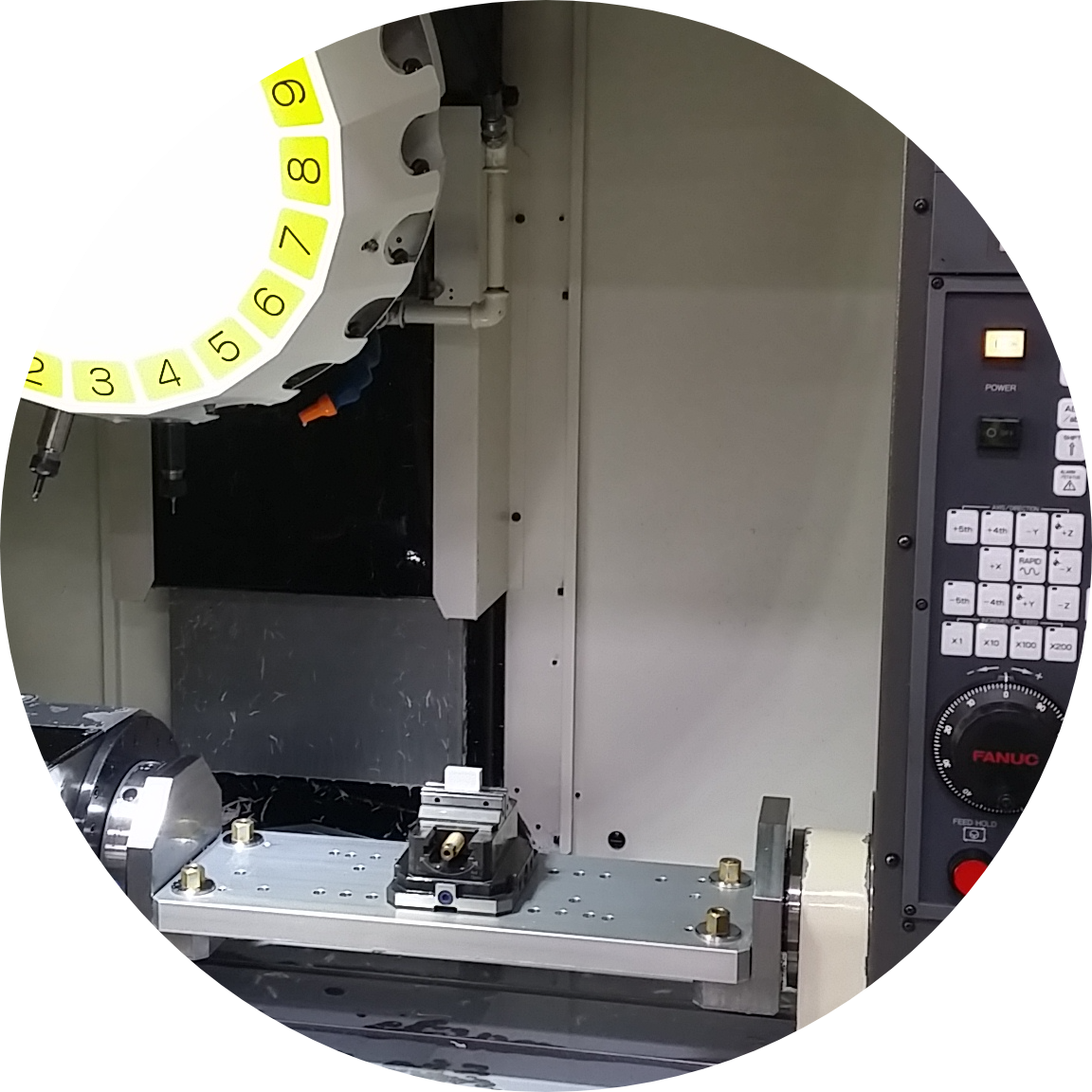

TECNOLOGY

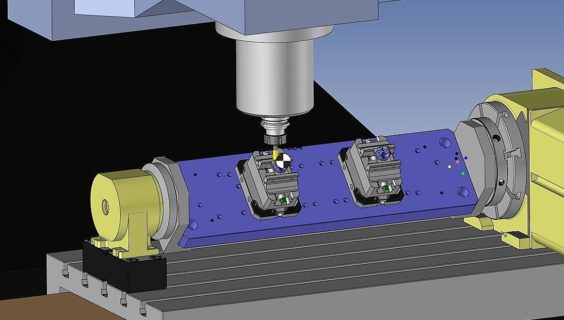

Two sections equipped with the most advanced CNC-Lathes and machining centers.

Double turret lathes with Y axis, lathes with sliding headstocks and 4 axis machining centers allow us to undertake each of our client’s needs.

SECTORS

RAILROAD

NAVAL

AERONAUTICAL

CAR

ENERGY

CHEMICAL

HEALTH

TEXTILE

FOOD

ENVIRONMENT

Environment care is one of our biggest concerns. That’s why we pay much attention in:

- Ensure that our every action respect the legal mandates regarding environmental issues

- Use in every fabrication process and its parallel works, the strictly necessary resources and the ones that are less dangerous for the environment.

- Rise conscience and awareness about environmental responsibility.