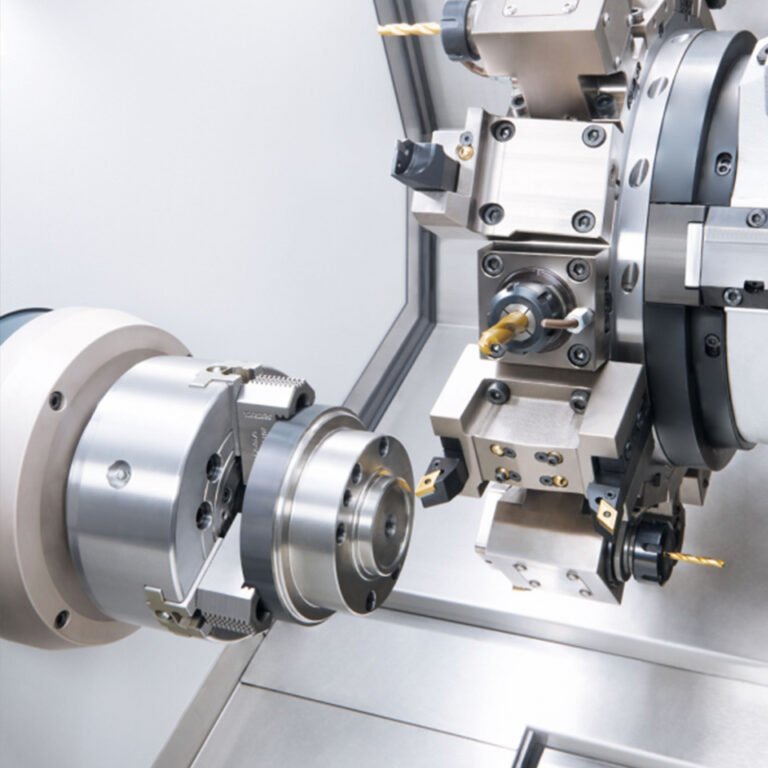

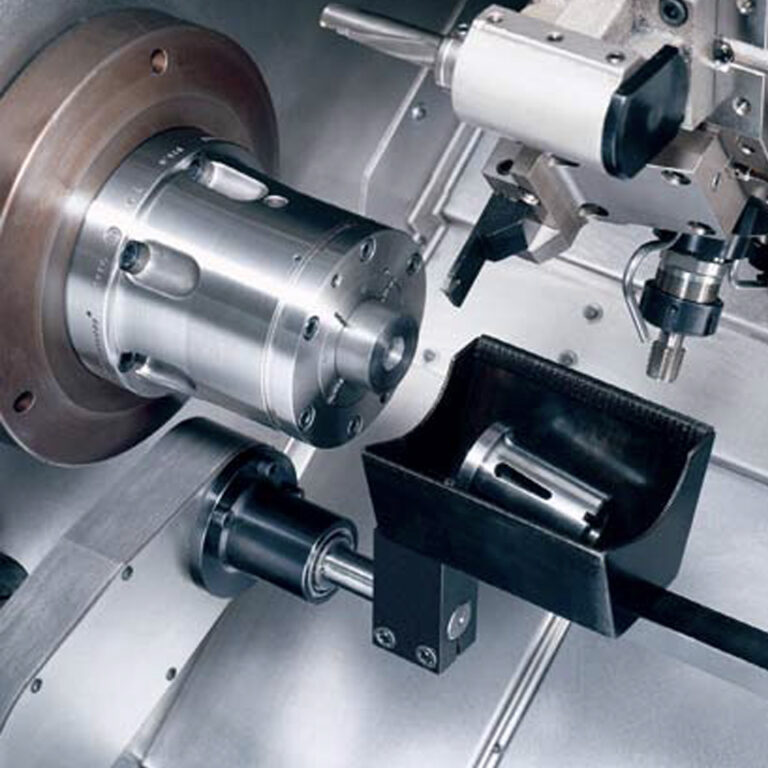

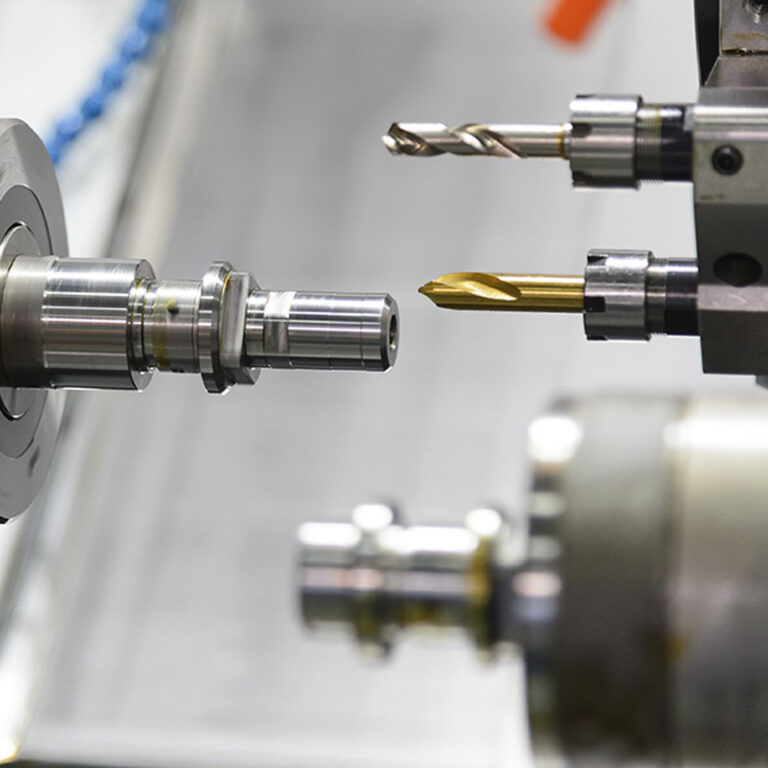

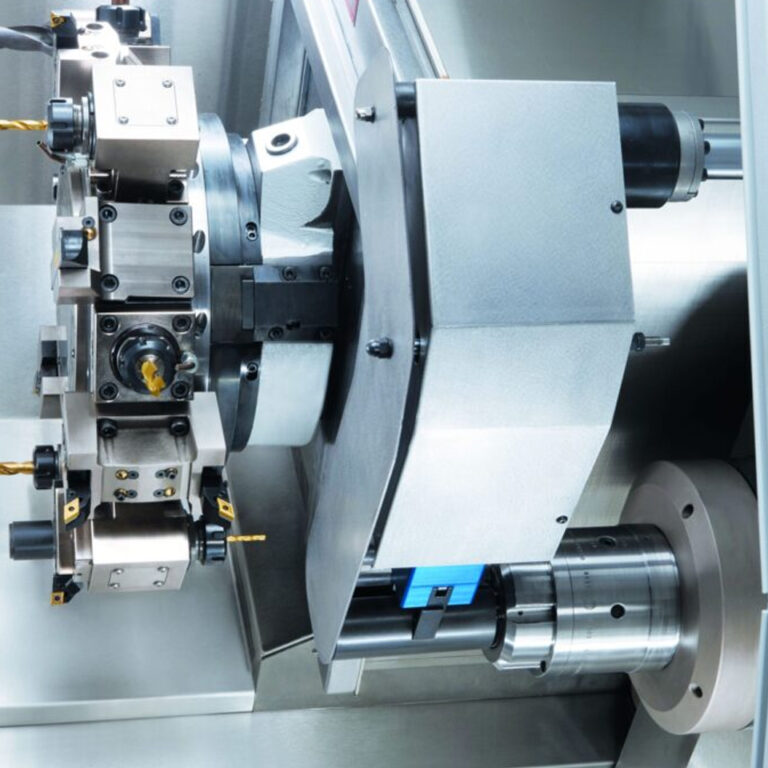

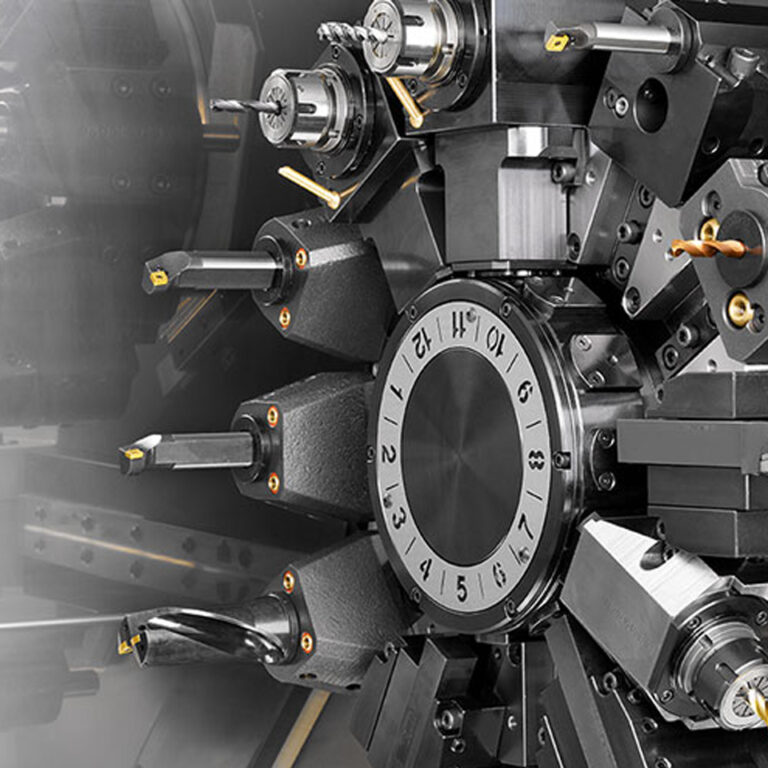

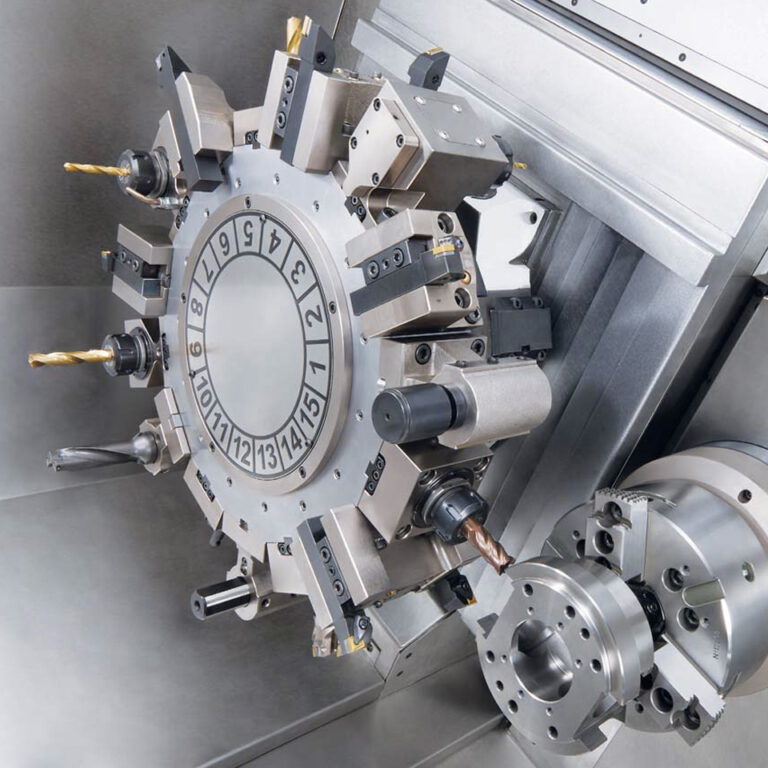

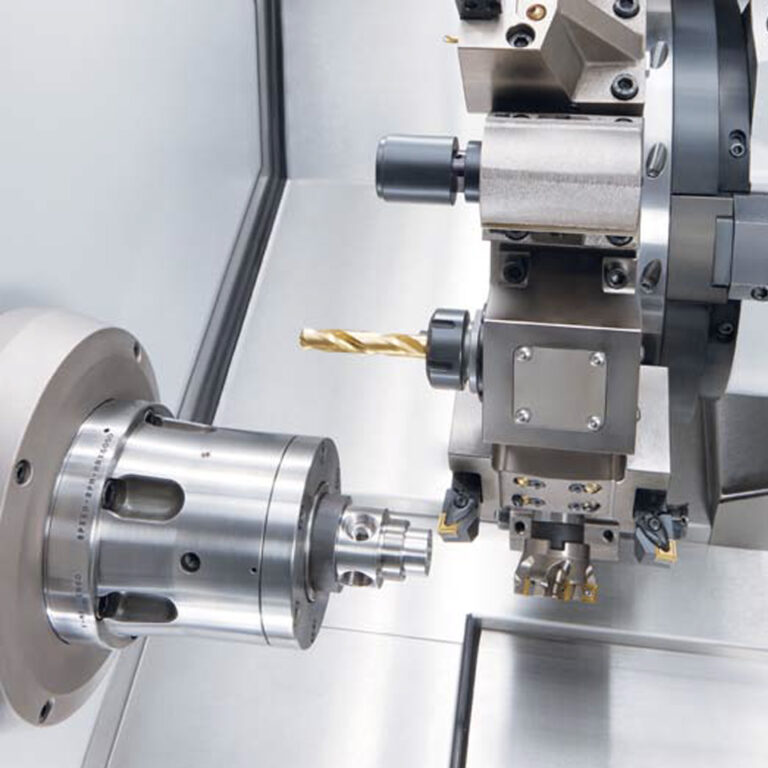

With automatic bar feeders and loaders and equipped with static and motorized tool holders.

Along with the main machinery we have accessory machinery such as cutting saws, drills, manual lathes and milling machines, hydraulic presses, threading machines, and equipment for lubrication and cleaning of parts.

Do you want to know more about our means of production?

Connect with Us. Visit us in person or engage with us on social media. We’re here to serve you and provide the solutions you need. Join us today!

Carrer de Sant Sebastià, 167 – 08203 – Sabadell, Barcelona

© Copyright 2023 Decolletatge Sabadell S.L. Todos los derechos reservados.