Last-Minute Excellence: Elevate Urgent Projects

We understand that time is often of the essence in your projects. That’s why we proudly offer our exclusive Immediate CNC Precision service. Imagine having outstanding results delivered right to your doorstep, not in weeks, but in a mere matter of hours and for a reasonable price. Don’t wait – secure your competitive edge today with our Immediate CNC Precision service and watch your projects soar.

Upload a file.

Offer delivered in less than 24 working hours.

Trough our website or by email

Choose between CNC milling and turning process. Wide range of materials.

In the realm of manufacturing, CNC (Computer Numerical Control) machining stands out as a paramount choice when compared to other production methods, such as 3D printing and plastic injection moulding.

These three manufacturing processes traverse a dynamic spectrum between subtractive and additive manufacturing technologies. However, CNC machining distinguishes itself by its transformation of solid materials through a precise cutting system. In contrast, additive processes involve the gradual buildup of a custom piece by melting or solidifying the material, layer by layer, depending on the type of 3D printing, ultimately yielding the final product.

The unparalleled advantage of CNC production lies in its ability to yield superior strength and durability, maintaining the tightest tolerances and achieving impeccable surface finishes.

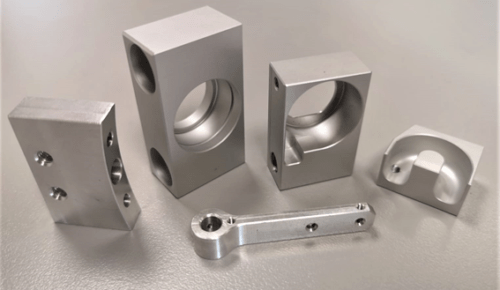

Explore the world of CNC Milling, a cutting-edge manufacturing system with capabilities spanning 3 and 5 axis processes.

We sculpt solid blocks into intricate molds, ultimately giving birth to the flawless final part you envision.

Our extensive material selection includes a wide range of options, with many readily available in stock to meet the demands of ever-shortening delivery times.

Some of our frequently utilized materials include:

Type material

■ Carbon steels

■ Stainless steels

■ Aluminum

■ Bronze

■ Copper

■ Brass

■ Titanium

Type material

■ PA

■ POM

■ PET

■ PTFE

■ PVC

■ PEEK

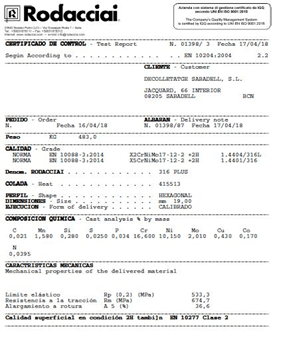

We possess the essential means and resources to provide the traceability and quality reports that meet the requirements of our clients. Our commitment to thorough documentation ensures your confidence in every piece we deliver.

To receive a quote for a part, please provide us with your email address and the 3D model. If you need help modelling your part in 3D, let us know and we will recommend a designer.

File Formats

The ProtoQuote® system accepts files in the following formats:

Our 3D printing service can also generate a quote from a Stereolithography file (.stl)

Do not hesitate to contact us, either by visiting us or through our social networks.

Carrer de Sant Sebastià, 167 – 08203 – Sabadell, Barcelona

© Copyright 2023 Decolletatge Sabadell S.L. Todos los derechos reservados.